Hand Tools: The Key to Efficient Work and Creative Living

I. Hand Tools - The Timeless Practical Choice

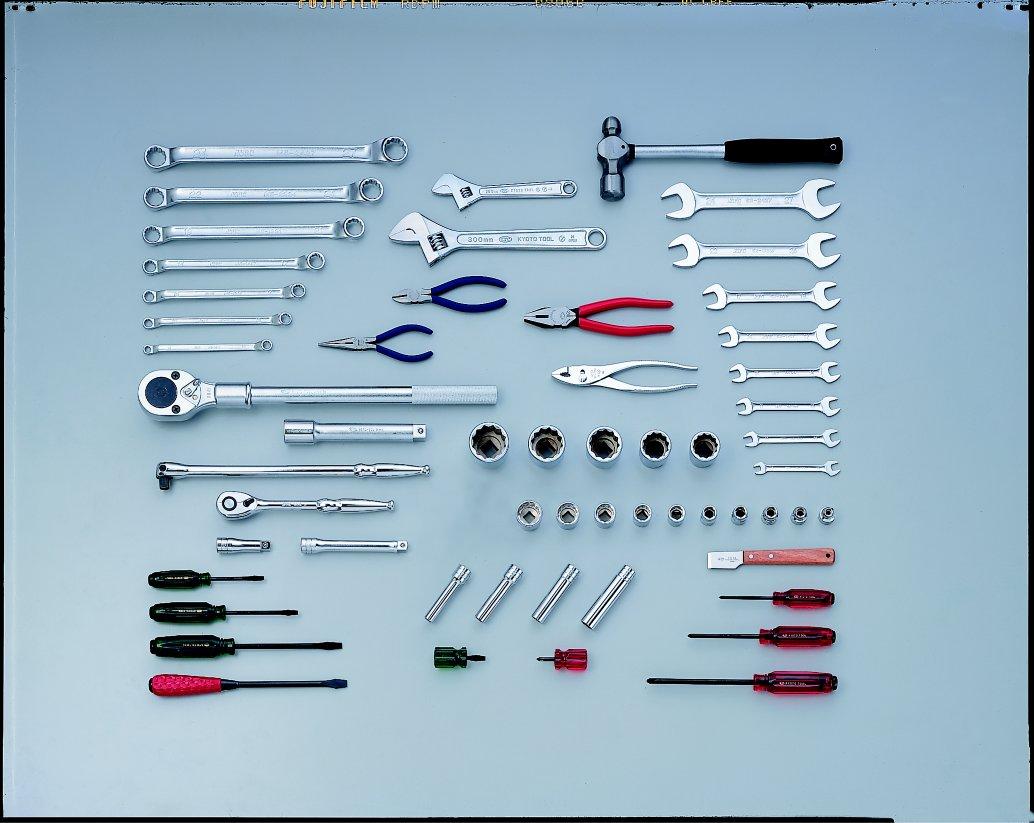

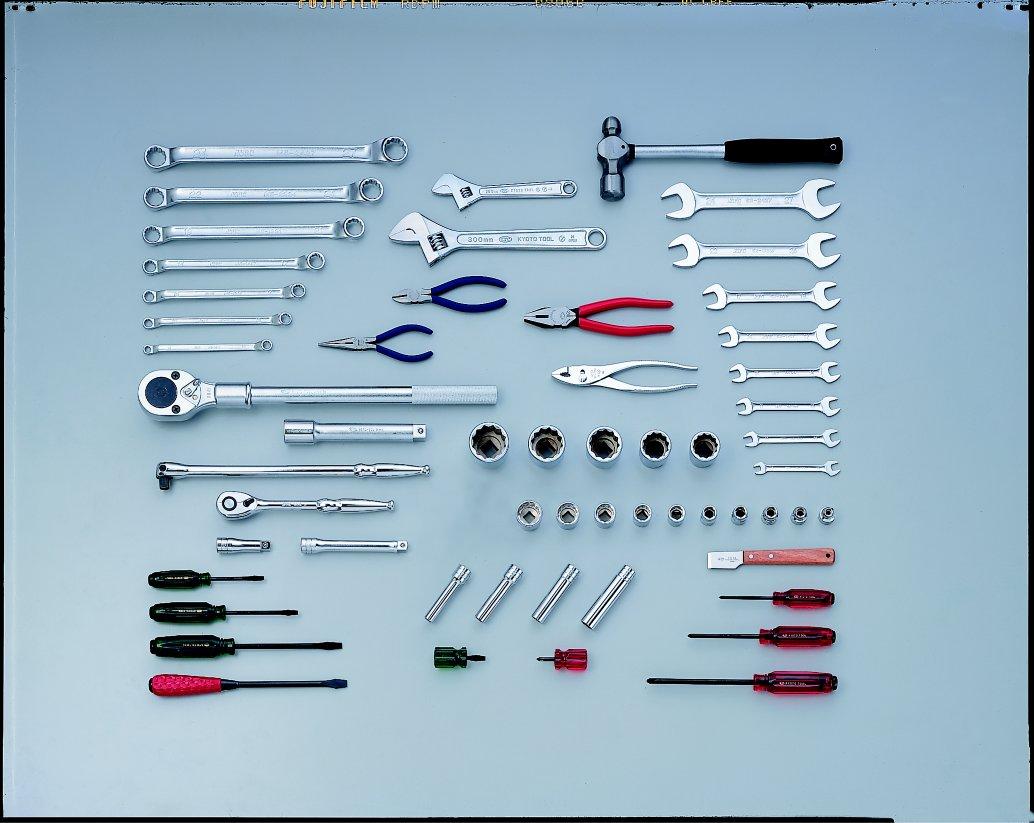

In the era of rapid technological development, although power tools continue to emerge, hand tools still occupy an irreplaceable position in the tool industry due to their unique advantages. Hand tools refer to tools driven by manual operation, such as wrenches, screwdrivers, pliers, hammers, saws, etc. They are compact, portable, easy to operate, and do not require a power source, making them suitable for various working scenarios and environments.

Hand tools play a crucial role in home maintenance, DIY projects, industrial manufacturing, construction, and other fields. At home, when we need to assemble furniture, repair pipes, or replace light bulbs, a set of handy hand tools allows us to solve problems easily without relying on professionals, saving time and costs. In industrial and construction fields, hand tools are essential for workers to perform precise operations and complete complex tasks, with flexibility and precision that power tools cannot match.

II. Introduction to Common Hand Tools

(1) Wrenches

Wrenches are tools for rotating fasteners like bolts and nuts. Common types include open-end wrenches, box wrenches, socket wrenches, and adjustable wrenches. Open-end wrenches have adjustable openings for different bolt/nut sizes; box wrenches feature hexagonal ends for a secure grip to prevent slipping; socket wrenches consist of multiple sockets and handles for complex scenarios; adjustable wrenches have a movable jaw for wide-ranging use.

(2) Screwdrivers

Screwdrivers are used to tighten or loosen screws. They are classified by screw head type: flat-head, Phillips, and hexagon screwdrivers. Flat-head screwdrivers fit slot-head screws, Phillips screwdrivers fit cross-head screws, and hexagon screwdrivers fit hexagon socket screws. Special types include magnetic screwdrivers and interchangeable-bit screwdrivers for different working environments.

(3) Pliers

Pliers are used for clamping, cutting, and bending metal wires. Common types include combination pliers, needle-nose pliers, diagonal cutters, and wire strippers. Combination pliers handle thick wires and heavy-duty cutting; needle-nose pliers work in tight spaces for delicate operations; diagonal cutters shear wires and cables; wire strippers remove wire insulation for easy wiring.

(4) Hammers

Hammers are for striking and knocking objects. Common types include claw hammers, 钳工锤 (industrial hammers), and rubber mallets. Claw hammers have a claw for pulling nails; industrial hammers deliver high-impact force for manufacturing and repair; rubber mallets protect fragile surfaces like glass and plastic.

(5) Saws

Saws cut materials like wood, metal, and plastic. Common types include hand saws, hacksaws, and coping saws. Hand saws cut wood, hacksaws cut metal, and coping saws create curved cuts for woodworking and metalworking.

III. Tips for Selecting Hand Tools

(1) Choose by Purpose

Clarify your usage needs first. Basic home maintenance requires a standard tool set (wrenches, screwdrivers, pliers, hammer), while professional industrial or construction work needs specialized, durable tools.

(2) Focus on Material Quality

Tool materials affect durability and lifespan. Common materials include steel, stainless steel, chrome vanadium steel, and carbon steel. Steel tools are hard and strong but prone to rust; stainless steel resists corrosion for wet environments; chrome vanadium steel offers high hardness and wear resistance; carbon steel is cost-effective but less durable. Choose based on usage environment and budget.

(3) Inspect Tool Quality

Check appearance (smooth surface, no burrs/cracks, even coating), handle grip (comfortable, balanced weight), and functionality (smooth operation, no slipping).

(4) Opt for Reputable Brands

Well-known brands ensure better quality and after-sales service, using strict quality control, premium materials, and advanced technology. Their extensive service networks provide timely support for issues.

IV. Maintenance and Care of Hand Tools

(1) Cleaning

Wipe off dirt and debris after use. For metal tools, use a damp cloth followed by a dry cloth; avoid corrosive cleaners on plastic/rubber parts.

(2) Lubrication

Lubricate moving parts (wrench joints, screwdriver shafts) regularly with oil or grease to reduce friction and extend lifespan, applying moderately to prevent dust accumulation.

(3) Rust Prevention

Store metal tools in dry, ventilated areas. Apply anti-rust oil or use anti-rust paper/bags to protect against moisture and corrosive gases.

(4) Storage

Keep tools in a dedicated toolbox or cabinet, classified by type to avoid damage and loss, ensuring easy access.