WhatsApp: +86 18713923349 Email: decii@shubing-trade.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-08-05 Origin: Site

In modern industrial machining, carbide rotary burrs have become an indispensable tool for improving efficiency and precision. From aerospace and automotive to mold manufacturing, various industries rely on these high-hardness, high-precision cutting tools for metal removal, weld cleaning, chamfering, and surface finishing. This article will explore the importance, different types, and advantages of carbide rotary burrs, citing relevant data and application examples to fully explain their critical role in the manufacturing industry.

Why are carbide rotary burrs so important?

Carbide rotary files are primarily made of tungsten carbide, which boasts a hardness exceeding HRA 90. Compared to high-speed steel (HSS) tools, they offer a service life approximately three to five times longer and can withstand higher cutting speeds and temperatures. According to a 2024 report by Global Market Insights, the global carbide tool market reached approximately $11.6 billion in 2023 and is projected to exceed $18 billion by 2030, with rotary files representing a significant growth share.

In industrial production, rotary files offer the following key advantages:

Rapid material removal, improving machining efficiency

Suitable for a wide range of materials, including steel, copper-aluminum alloys, stainless steel, and cast iron

Ability to reach difficult-to-reach, complex workpiece areas

Reduced manual grinding, improving consistency and safety

These characteristics make rotary files a key tool in applications such as automotive parts, mold finishing, and metal engraving.

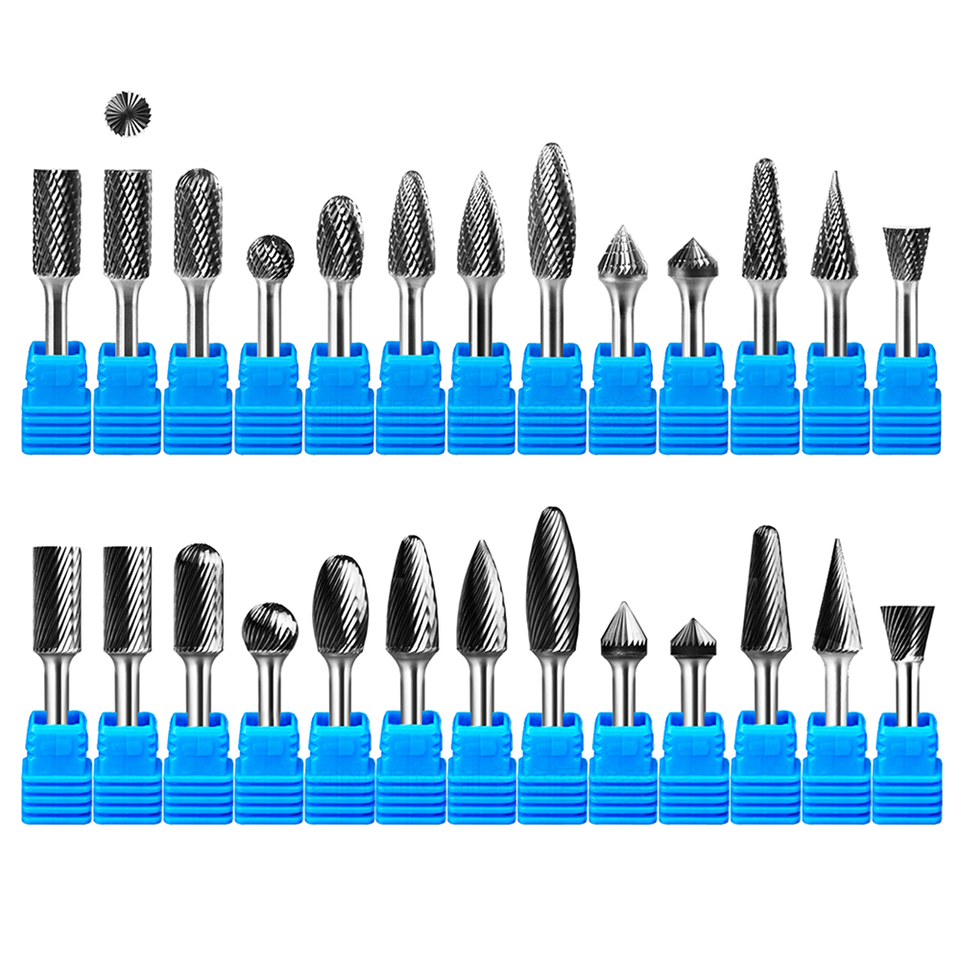

Common Carbide Rotary File Types

Carbide rotary files are categorized into various types based on their tip shape and tooth profile, each suited to different process requirements:

1. Ball-Shaped

Suitable for trimming grooves, internal angles, and hemispherical surfaces. Widely used for trimming mold cavities and castings.

2. Cylindrical

Suitable for flat machining and hole cleaning, suitable for trimming smooth surfaces and chamfering edges.

3. Oval (Egg)

Suitable for engraving and mold forming, and flexible in confined areas.

4. Tapered

Mainly used for precision milling and hole chamfering, suitable for machining tasks requiring precise depth control.

5. Standard/Cross Tooth Profile (Single/Double Cut)

Single Tooth Profile**: High cutting efficiency, suitable for removing large amounts of metal

Double Tooth Profile**: Smoother machining, suitable for fine finishing and burr reduction

These different tooth shapes and profiles offer great flexibility to address a variety of complex metalworking challenges.

Advantages and Application Examples of Carbide Rotary Files

Advantage Overview:

| Advantages | Description |

| High Hardness and Wear Resistance | Suitable for Continuous Machining of High-Hardness Materials |

| Saves Processing Time | High-Speed Cutting Reduces Cycle Time |

| Versatility | Suitable for Cutting, Deburring, Chamfering, Weld Cleaning, and More |

| Reduces Labor Intensity | Reduces Dependence on Manual Grinding, Improving Work Efficiency and Safety |

| Compatible with Various Equipment | Supports Pneumatic Mills, Electric Grinders, CNC Machines, and More |

Actual Application Cases:

1. Automotive Parts Processing

A German automotive parts manufacturer reduced part processing time by 40% by replacing traditional grinding methods with carbide rotary files. Product consistency was significantly improved, and the defect rate dropped to 0.5%.

2. Mold Manufacturing

A Taiwanese mold factory uses olive-shaped rotary files for micro-finishing mold cavities. Compared to the diamond grinding heads they previously used, this reduces tool replacement frequency by half, significantly reducing maintenance costs.

3. Aircraft Maintenance Industry

In aircraft maintenance, carbide rotary files are used to remove weld defects and corroded areas. This is more than three times faster than traditional steel files, significantly improving maintenance efficiency and safety.

Future Development Trends and Recommendations

With the growing demand for smart manufacturing and high-precision machining, the demand for high-performance rotary files in CNC and automation equipment will continue to rise. Future product design trends include:

* Nano-coating technology: Improving surface wear resistance and heat dissipation

* Composite tool tips: Reducing vibration and extending tool life

* Replaceable tool tip systems: Reducing overall consumable costs

For companies, choosing the right carbide rotary file not only optimizes machining processes but also provides a technological advantage in a highly competitive market.

Conclusion

Carbide rotary files, as the "precision engravers" of metalworking, not only improve work efficiency but also ensure product quality and process consistency. With the continuous advancement of tool design technology, their application scope is rapidly expanding. For professionals engaged in metalworking, mold making, or equipment maintenance, a thorough understanding and appropriate selection of rotary files is a key step to improving productivity and market competitiveness.

---